Pinch Valves

Pinch valves are widely used in various industrial applications. They are full bore type of control valve. There is no obstruction to flow passage. These kind of valves are ideally suited for the handling of slurries, liquids with large amounts of suspended solids.

They are used in systems that convey solids pneumatically. Pinch valve are linear action valves that can be used in both an off / on manner or in throttling service or in a variable position. They are supposed to be the simplest in any valve design. Pinch valves are used in various applications like are medical, pharmaceutical, slurries, pulp, powder, pellets and wastewater.

Materials used:

- Stainless steel

- Cast iron

- Carbon steel

- Brass

- Bronze

- Plastic

- Rubber

- Steel etc.

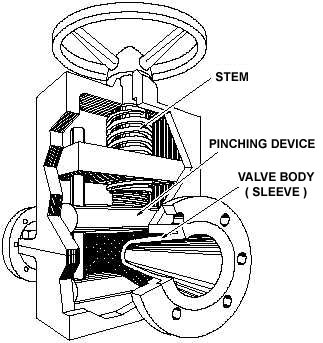

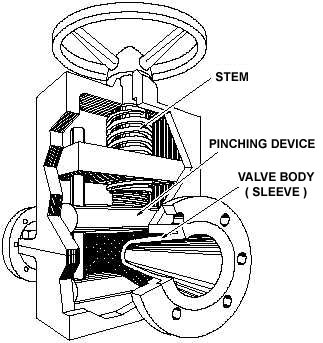

Parts of Pinch Valves:

Major components of a pinch valve are as follows:

- Stem

- Body (Sleeve)

- Pinching device

The pinch valve consists of a sleeve and a pinching mechanism. The

sleeve is the pinch valve body and made of such materials which are

corrosion resistant. All of the operating portions are completely

outside to the valve. Sleeves come with either with a flanged end having

standard dimensions or extended hubs and clamps designed to slip over a

pipe end. The sleeve will contain the flow media.

How does a pinch valve operates?

How does a pinch valve operates?

Pinch valves are closed either by fluid actuation or manual means.

Electro-mechanical closure takes place by actuating a solenoid, which in

turn lowers a bar or gate onto the sleeve, cutting off the flow. With

fluid actuated pinch valves, the pinching action is completed by air or

hydraulic pressure placed directly on the elastomer sleeve. The pinch

valve body acts as a built-in actuator, which eliminates costly

hydraulic, pneumatic, or electric operators. The pinch valve is closed

mechanically with the movement of the pinch bars located on opposite

sides of the sleeve.

Uses of Pinch Valves:

- Pinch Valves help in installation in grooved-end piping.

- They offer position indication and noise reduction.

- They handle aggressive, particulate-laden liquids.

- They are suitable for on/off fluid control applications.

- Pinch Valve controls viscous, abrasive and corrosive fluids.

- Pinch valves are suitable for high purity applications.

- They are used for both manual and automatic throttling.

- They are used in the waste treatment plant.

- They are useful in the handling of lime slurry and

carbon-impregnated activated sludge.

- Pinch Valves are considered to be reliable, maintenance-free,

cost-effective valves.

- They are capable of handling the most abrasive, tough slurries,

dry solids in process industries and corrosive chemical

applications.

- Pinch valves are used in various applications in wastewater and

raw water applications.

- They help cut maintenance costs in abrasive service.

The following flow chart will give us an idea as to why

should we use pinch valve:

Applications

of Pinch Valves:

Pinch Valves are just ideal to solve all process problems which are

associated with abrasive or corrosive fluid handling in various areas

like:

- Pulp and paper

- Mineral processing

- Food

- Power generation

- Chemical handling

- Effluent treatment

- Water and wastewater etc.

The points mentioned below will be a guide for the buyers: