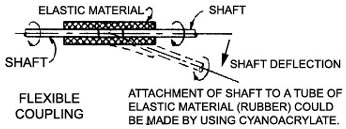

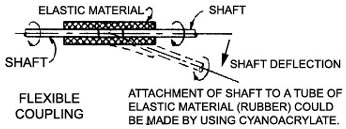

Flexible Coupling

A flexible coupling is used to connect two shafts, end-to-end in the same line, for two main purposes. The first purpose is to transmit power that is torque from one shaft to another, thereby causing both to rotate in unison, at the same RPM. The second purpose is to compensate for small amounts of misalignment and random movement between the two shafts.

Flexible couplings are made of elastic materials, like rubber, or have various other configurations. During rotation, flexible couplings can accommodate misalignment and motion.

How flexible coupling operates?

It is a known fact that in any direct mechanical drive system, there is

the need to couple the variety of driven elements that are included. The

majority of drive elements which include gear reducers, lead screws, and

a host of other components, are driven by shafting. The shafting is

supported by multiple bearings. This allows the shafting to be held

extremely straight and rigid while rotating which at the same time avoid

any kind of possible balancing and support problems. Because of this

rigid support, it practically becomes impossible to avoid slight

misalignments between a driving and driven shaft when they are

connected.

The simple and most common solution to the problem of shaft

misalignment is using a flexible coupling to absorb lateral, angular,

and axial restoring forces, while maintaining some rigidity or fixed

position in rotation. The degree to which this torsional rigidity is

applied varies from one application to another. The basic function of

flexible coupling is to join two pieces of rotating equipment while

permitting some degree of misalignment or end movement or both.

Materials used:

Various materials are used to make flexible couplings like as follows:

- Brass

- Aluminum

- Cast Iron

- Stainless Steel

- Carbon Steel

- Rubber etc.

Types of flexible coupling:

There

are three basic types of flexible couplings. They are as follows:

- Mechanically Flexible Coupling: The mechanical flexible

coupling generally obtain their flexibility from loose-fitting parts

or rolling or sliding of mating parts or from both.

- Metallic Element Coupling: The metallic flexible

couplings obtain their flexibility from the flexing of thin

metallic, disc or diaphragms.

- Elastomeric Element Coupling: The elastomeric element

flexible coupling obtain their flexibility from stretching or

compressing a resilient material like for example rubber or plastic.

Buying tips When searching for flexible couplings, some

mechanical properties that are to be considered are as follows:

- Rated torque: This is the maximum service torque for

which coupling is rated.

- Rated speed: This is the maximum rated rotational

speed of coupling.

- Stiffness: This is expressed in torque per unit

angular deformation.

- Backlash: This is the rotational position loss in a

direction change.

- Performance:

- The most common flexible coupling recommended for

general-purpose equipment alignment should be one within

0.001 inch/inch of separation between flex points.

- For high-speed applications like over 3600 rpm, alignment

should be within 0.0005 inch/inch of separation between flex

points.

- For general-purpose equipment and couplings, the

alignment should be “zero” align statically.

- When alignment is carefully done initially, there should

be enough capacity left in the flexible coupling to handle

more misalignment during operation.

|

Functions of flexible coupling:

There

are three basic functions of a flexible coupling. They are as follows:

- Transmit power: Flexible couplings are used to transmit

mechanical power from one machine to another. The mechanical power

is in the form of torque at some speed, or work per unit of time, In

general, the power lost by a flexible coupling is small.

- Accommodate misalignment: There are two types of

misalignment. They are shaft misalignment and coupling misalignment.

Both the misalignments are accommodated through flexible coupling.

- Compensate for end movement: Most flexible couplings are

designed in such a way that they can accommodate axial movement of

the connected equipment or shaft ends.

Applications of flexible couplings:

- Off-highway vehicles

- Agricultural machinery

- Marine propulsion

- Rail traction

- Pump sets etc.

Conclusion:

The flexible couplings are available from a large number of different

manufacturers, each of which designed them with specific applications in

mind. Ideal linkage can be achieved for any motion system with proper

selection of the right flexible coupling for any application.

The points mentioned below will be a guide for the buyers:

Various materials are used to make flexible couplings like as follows:

Various materials are used to make flexible couplings like as follows:

There

are three basic types of flexible couplings. They are as follows:

There

are three basic types of flexible couplings. They are as follows:

There

are three basic functions of a flexible coupling. They are as follows:

There

are three basic functions of a flexible coupling. They are as follows: