Pipe Coupling

Pipe couplings are highly demanded in the pipe fitting market. Pipe couplings are fittings that help to extend or terminate pipe runs. These fittings are also used to change pipe size. Couplings extend a run by joining two lengths of pipe. They are known as reduced coupling if they are used to connect pipes of different sizes.

Couplings are also known as repair couplings. These couplings are without stops or ridges and they can be fixed anywhere along the pipe length for preventing leak of any kind.

Salient Features:

Some important features of couplings are as follows:

- Couplings come in all standard pipe sizes and are available for

almost all types of pipe.

- Available in several finishes.

- Mostly cylindrical in design.

- Couplings compensate for axial, lateral and angular shaft

misalignment.

- Couplings operate in quiet and smooth way.

- There is a great degree of torsional stiffness.

- There is the right angular transmission of angular motion and

torque.

- Usually long life.

- Easy mounting and dismounting.

- Low lateral stiffness etc.

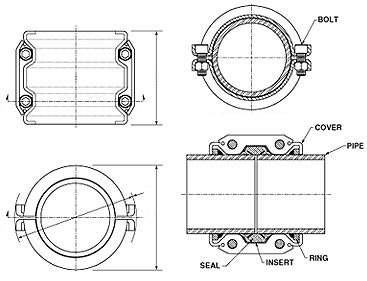

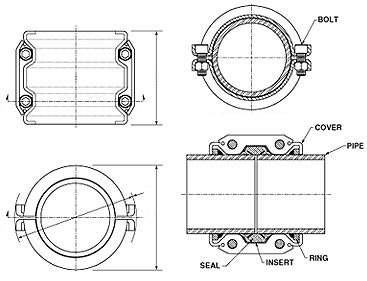

Parts of Pipe Coupling as shown below:

Materials Used:

Materials Used:

Pipe couplings are made of various materials and the buyers should

always consider the material used for making them. Some of the materials

used for making couplings are:

- Brass

- Aluminum

- Cast Iron

- Stainless Steel

- Copper

- Bronze etc.

Designs on couplings:

Couplings are available in various shapes and forms. The various

designs available on couplings can be as follows:

- Grid type

- Gear type

- Disc type

- Rubber/Elastomer element type

- Fluid Couplings

Areas of application for couplings:

Besides being used as an important pipe fitting, couplings are also

used in the following:

- Machine tools

- Assembly machinery

- Industrial robots

- Automated plants

- Printing machinery

- Servo drives

- Robotic axes

- Manipulators

- CNC milling / grinding

- Linear actuators

- Packaging machinery

- Woodworking machinery

- Textile machinery

- Printing machinery

- Metal cutting machinery etc.

Buyer's guide

How to evaluate the couplings? There is a long list of

evaluation factors that affect the type of coupling best suited for

an application. It is not necessary that all couplings will have all

the features. The factors to be considered are as follows:

- Design Adaptability

- Alignment Capabilities

- Axial Freedom

- Backlash

- Chemical Resistance

- Damping Capacity

- Ease of Installation

- Fail Safe or Fusible Link

- Field Repairable

- High Speed Capacity

- Inherent Balance

- Maintenance Required

- Number of Component Parts

- Reciprocating Drivers and Loads

- Temperature Sensitivity

- Torque Capacity to Diameter

- Torque Overload Capacity

- Torsional Stiffness

|

Types of Couplings:

Couplings are an integral part of pipe fittings and are of various

types like:

The points mentioned below will be a guide for the buyers:

Materials Used:

Materials Used: