Globe Valve

Globe valves are popular type of pipe valves. Globe valves are linear motion valves and are so called because of their spherical design. The spherical design is a popular, ancient design for globe valves, though nowadays many modern globe valves do not have much of a spherical shape.

They are available in various sizes, materials and finishes depending on the application in which they are applied. The globe valves are widely used in the petrochemicals, electricity, gas and water supply sectors. They are used to regulate fluid flow in both on/off and throttling service.

Materials used:

- Gun Metal

- Cast Steel

- Stainless Steel

- Cast Iron

- Alloy Steel

- Brass

- Bronze

- Aluminum

- Zirconium

- Plastic etc.

Buying TipsProper material compatibility needs the

knowledge of the type, temperature and concentration of the media

being handled. It may be necessary to consult the manufacturer of

the globe valve for specific properties of the materials used in the

valve. Some features to look for are as follows:

- Design standard

- Material of construction

- Size range

- Pressure rating

- Ends:

- Screwed

- Flanged

- Socket weld

- Butt weld

- Durability Repair and maintenance

|

Designs of Globe valves:

Globe valves are available in three main body designs, They are as

follows:

- Angle design: The inlet and outlet are perpendicular to

each other and the purpose is to transferring flow from vertical to

horizontal.

- Y-design: Here, the gate valve derives its linear action

from the incline between the inlet's axis and outlet ports.

- Multi-piece design: In the multi-piece design, the bodies

of valves are bolted together and here the inlet and the outlet are

not of single piece construction.

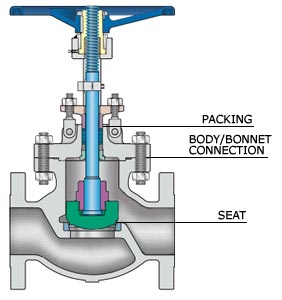

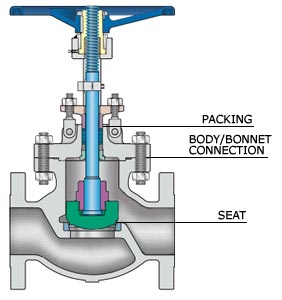

Parts of globe valves:

Globe valves are usually two-port valves. Ports are openings in the

body for fluid or any form of liquid flowing in or out. The two ports

can be straight across from each other on the body, or can be angle

oriented. The two halves of the globe valve are separated with the help

of an internal baffle. This has an opening forming a seat onto which a

movable disc can be screwed in to close the valve. In globe valves, the

disc is connected to a stem which is operated by screw action or when it

is manually operated, the stem is turned by a hand wheel. In other

words, globe valves consist of the following movable parts:

- The disk

- The stem, and

- The handwheel

The stem is the connection between the handwheel and the disk.

A diagrammatic representation of a

globe valve

Salient features of globe valves:

Salient features of globe valves:

- Most globe valves have outside screw rising stem construction.

Here the threads are away from the line fluid and hence they are

easy to lubricate.

- Available in hand wheel operated designs.

- In all globe valves, there are the back seat ring features that

facilitate repacking of the stuffing box on line with the valve in

fully open position.

- Seat ring which is screwed into the body are replaceable.

- Body & bonnet with liberal sections.

- The globe valves of higher pressure and larger sizes are provided

with thrust bearings and also with gear drive arrangements.

- Body spherical form of globe valves, allows for the stresses,

turbulence and resistance to flow to be kept to a minimum.

Uses of globe valves:

- Globe valves are used where throttling is required.

- They are also used where both throttling and shut-off required.

- Globe valves can also be used for on-off service.

- They are mostly confined to those applications where the valve is

normally closed and drop is not important when the valve is open.

- They are also commonly used in those situations where minimum

pressure drop and bidirectional on-off service is required.

- Globe valves are used as sampling valves, which are normally shut

except when liquid samples are being taken.

The points mentioned below will be a guide for the buyers:

Salient features of globe valves:

Salient features of globe valves: